Steel Types Used in Sword Making: A Guide for Collectors and Enthusiasts

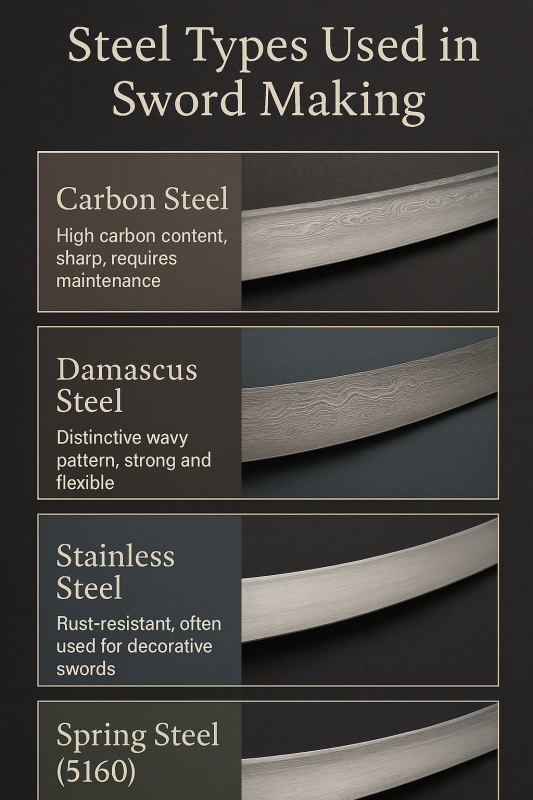

Steel Types Used in Sword Making

When it comes to crafting handmade swords, one of the most critical decisions a swordsmith makes is the choice of steel. Different types of steel determine not only the blade’s strength and sharpness but also its durability, flexibility, and aesthetic appeal. Whether you’re looking to buy katana online, admire a Zulfiqar sword, or commission custom swords, understanding the steel behind the blade adds depth to your appreciation.

Why Steel Matters in Sword Making

Steel is an alloy of iron and carbon — but not all steels are created equal. The amount of carbon, the forging technique, and the presence of other elements (like chromium or vanadium) drastically change the sword’s characteristics.

For handmade swords, the steel must strike the perfect balance between hardness (for a sharp edge) and flexibility (to prevent breaking).

Most Popular Steel Types in Handmade Swords

- Carbon Steel

- Common Grades: 1045, 1060, 1095

- Traits: High carbon steels are known for their sharpness and durability. The higher the carbon content, the harder and sharper the blade — but also more brittle if not properly tempered.

- Best For: Custom swords and collectors who want high-performance and historical accuracy.

- Downside: Requires regular oiling to prevent rust.

- Damascus Steel

- Visual Appeal: Famous for its wavy patterns across the blade surface.

- Traits: Combines layers of different steels to produce a strong, flexible, and visually unique blade.

- Historical Use: Widely used in Middle Eastern weapons, including the legendary Zulfiqar sword.

- Best For: Aesthetic collectors and traditionalists.

- Stainless Steel

- Traits: Contains chromium, making it rust-resistant and ideal for display swords.

- Downside: Typically not used for functional blades due to brittleness.

- Best For: Decorative or ceremonial handmade swords.

- Spring Steel (5160)

- Traits: Highly durable and flexible, originally used in car leaf springs.

- Best For: Functional battle-ready swords and reenactment blades.

- Example Use: Commonly used in Ottoman sword reproductions designed for actual cutting.

Traditional vs. Modern Steel

Traditional swordsmiths, especially in Japan, used tamahagane — a special steel types made from iron sand. This was used in forging the legendary katana, where the smith would fold the steel multiple times to remove impurities.

Today, modern metallurgy offers advanced alloys with superior strength and consistency. But many collectors still favor traditionally folded steel types for its authenticity and connection to history.

Choosing the Right Steel for Your Sword

When choosing a handmade sword, consider:

- Purpose: Will it be displayed or used for practice/cutting?

- Style: Do you prefer historic accuracy or modern functionality?

- Maintenance: Some steels require more care than others.

If you’re browsing to buy katana online, or seeking a replica Ottoman sword or custom Zulfiqar sword, ask about the steel type used. It can greatly impact both the sword’s value and performance.

The Sword Crafting Process and Steel Selection

The selection of steel is just the beginning of the sword-making process. Once the appropriate steel is chosen, the blade is forged using techniques passed down through generations. A blacksmith will carefully heat the steel, fold it (in the case of Damascus steel), and shape it into a blade. The steel’s composition directly affects how the sword will respond to these processes.

In addition to steel, the heat treatment process is crucial. Heat treatment involves heating the steel to a high temperature and then quenching it rapidly in water or oil to harden it. This process enhances the hardness and edge retention of the blade, which is essential for both cutting performance and durability.

Conclusion

The choice of steel plays a fundamental role in the creation of handmade swords. Whether it’s the durability and sharpness of high-carbon steel or the unique patterns of Damascus steel, each type of steel offers distinct advantages for different sword-making purposes. By understanding the properties of these materials, sword makers can craft blades that are not only beautiful but also functional. If you’re interested in purchasing a custom sword or learning more about the steel types used in sword making, be sure to explore our collection at swordbuy.co.

Looking for high-quality handmade swords crafted from the finest steel? Explore our collection at swordbuy.co